info@gerb.com

Protecting Elbphilharmonie from sound transmissions

In 2017 Hamburg received a new landmark.

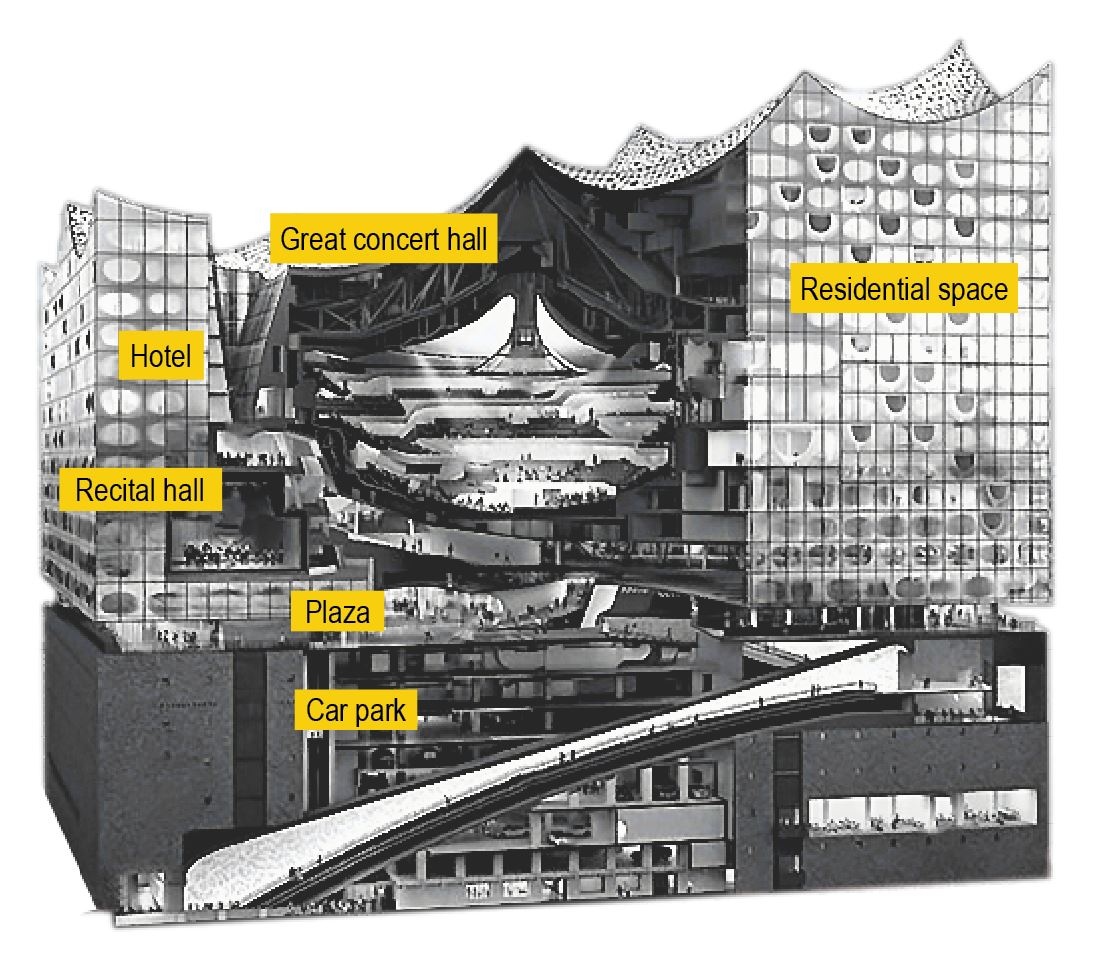

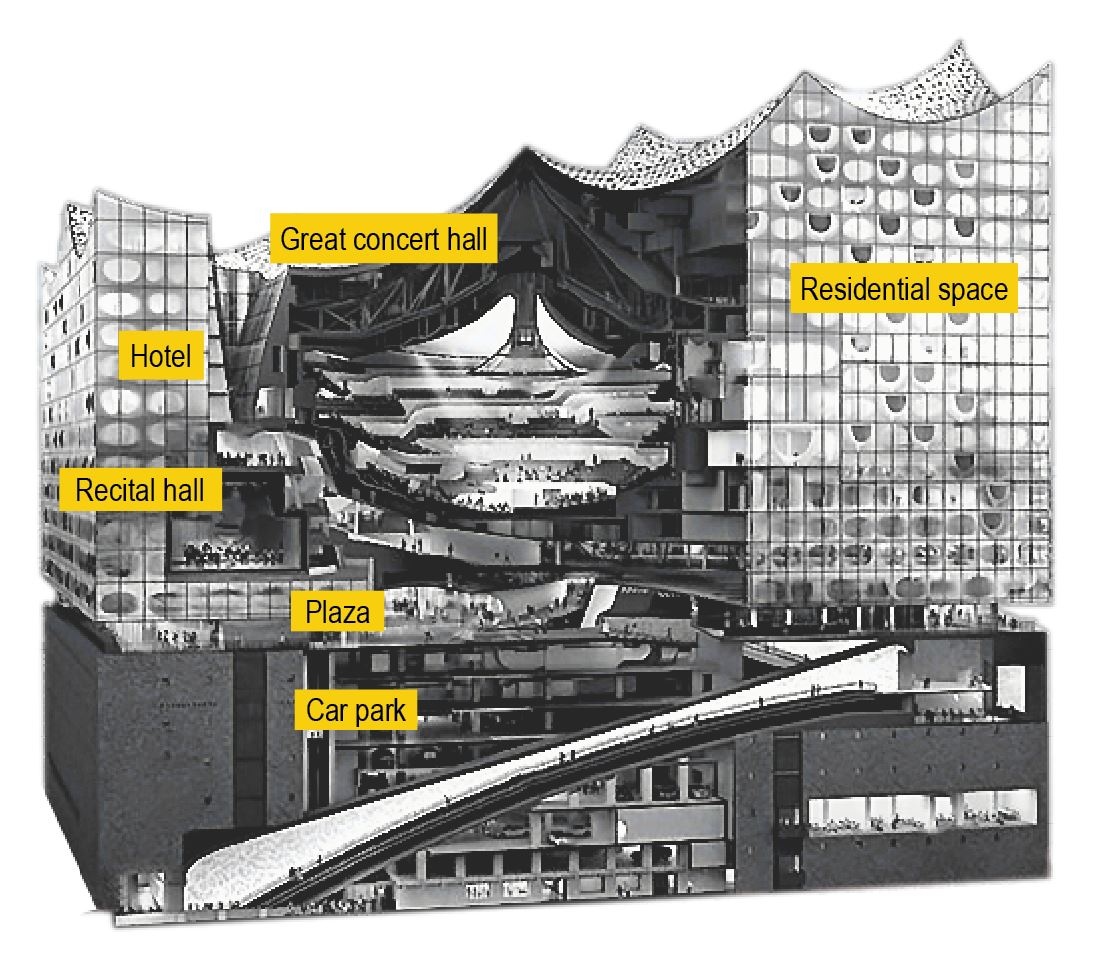

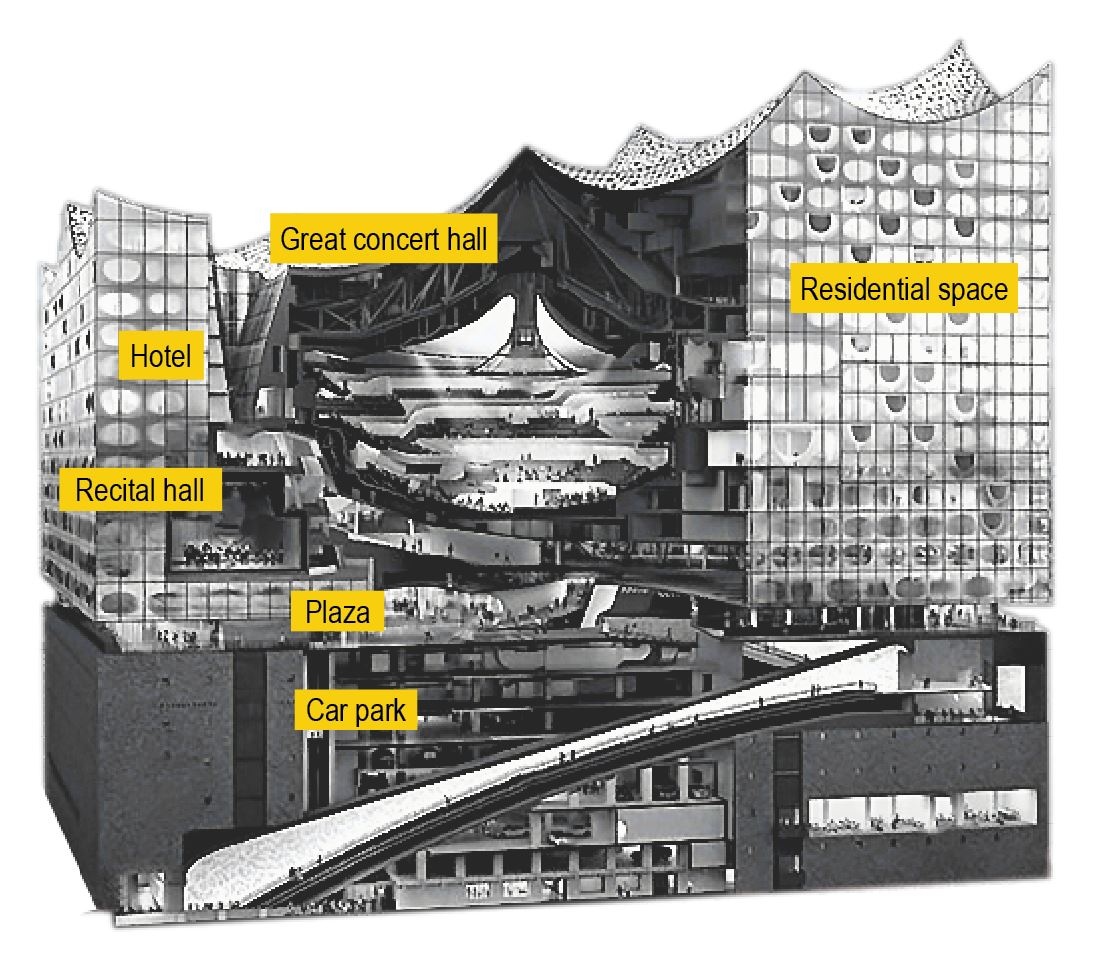

The Elbphilharmonie is located south of the Speicherstadt, the

historic warehouse district in the Port of Hamburg, Germany. The

Elbphilharmonie was built on an existing structure of a brick quay warehouse and claims to be a „cultural monument for everyone“. The building consists of different areas, concert halls and public areas as well as hotel and residential uses.

Challenge

The Great Concert Hall, the heart of the Elbphilharmonie, offers a soundscape that inspires. The sound architecture comes from the world-renowned acoustic designer Yasuhisa Toyota. Classical music has to sound perfect – not only does the shape of the hall play a decisive role here, but also noise coming in from outside has to be eliminated. Low-frequency sound from ship‘s horns and impact noise from the environment could penetrate the hall as structure-borne noise.

In addition, the building around the concert halls has to be protected from the music to ensure a quiet atmosphere in the surrounding hotel and residential areas during concerts.

Solution

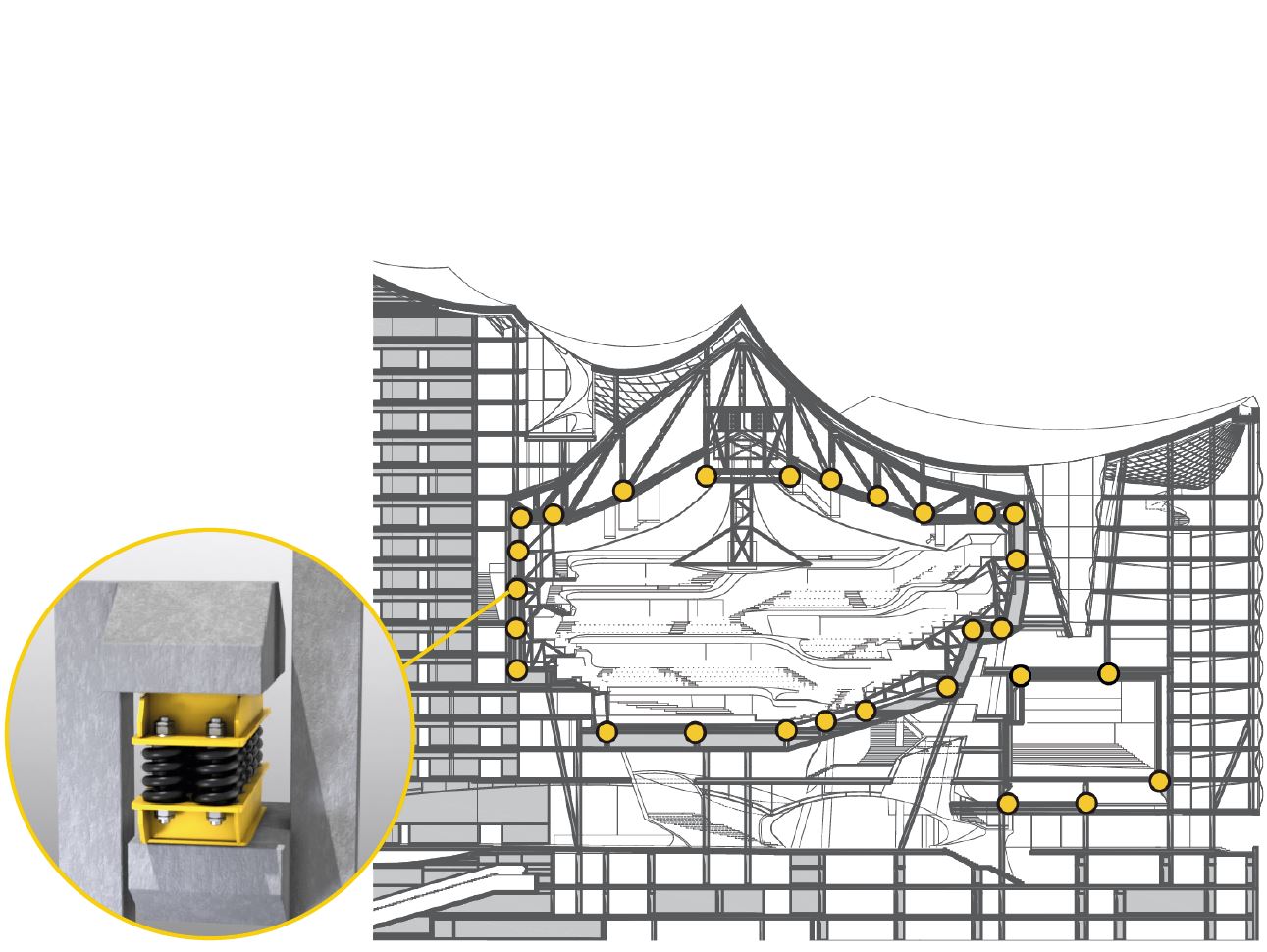

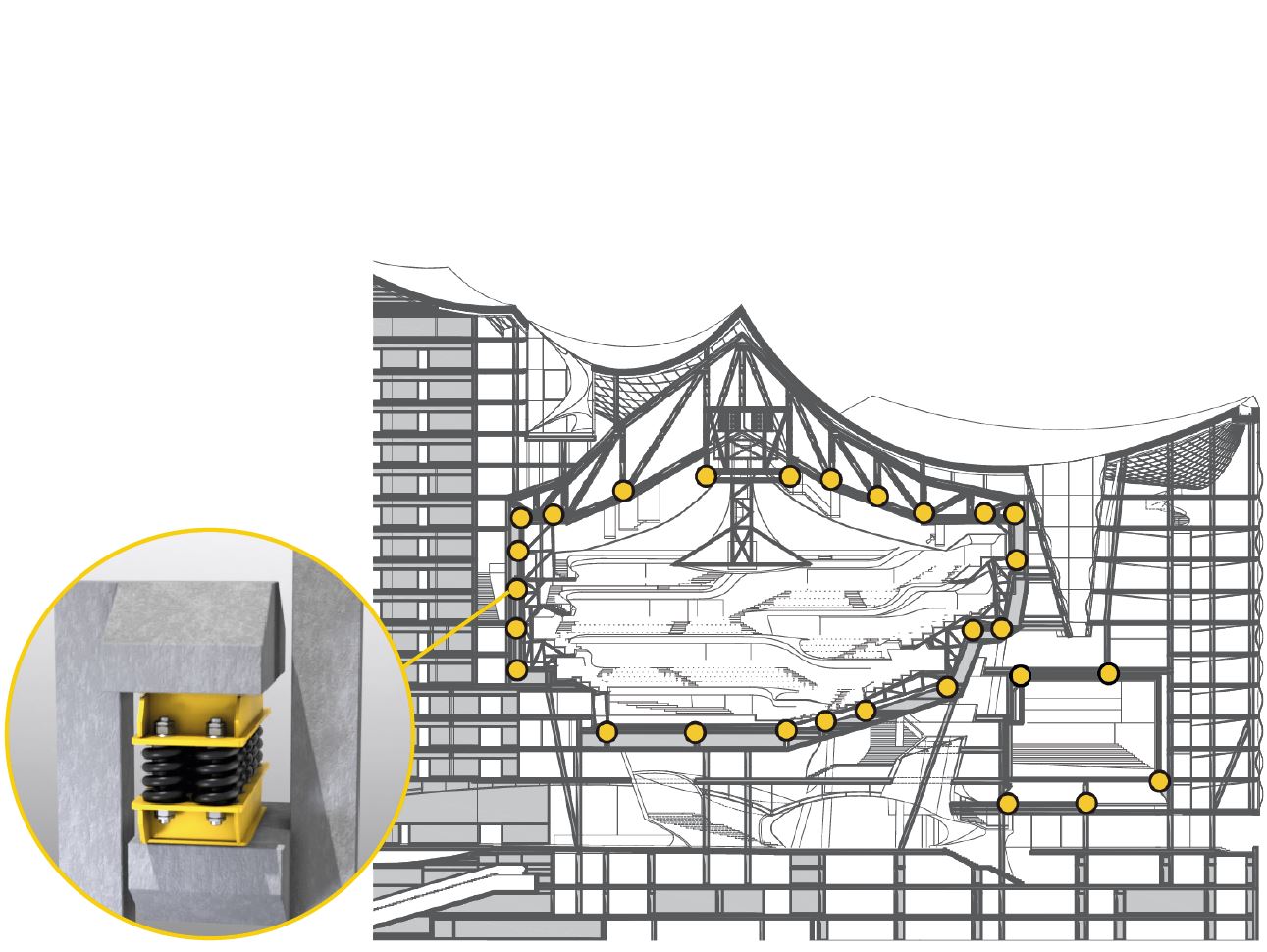

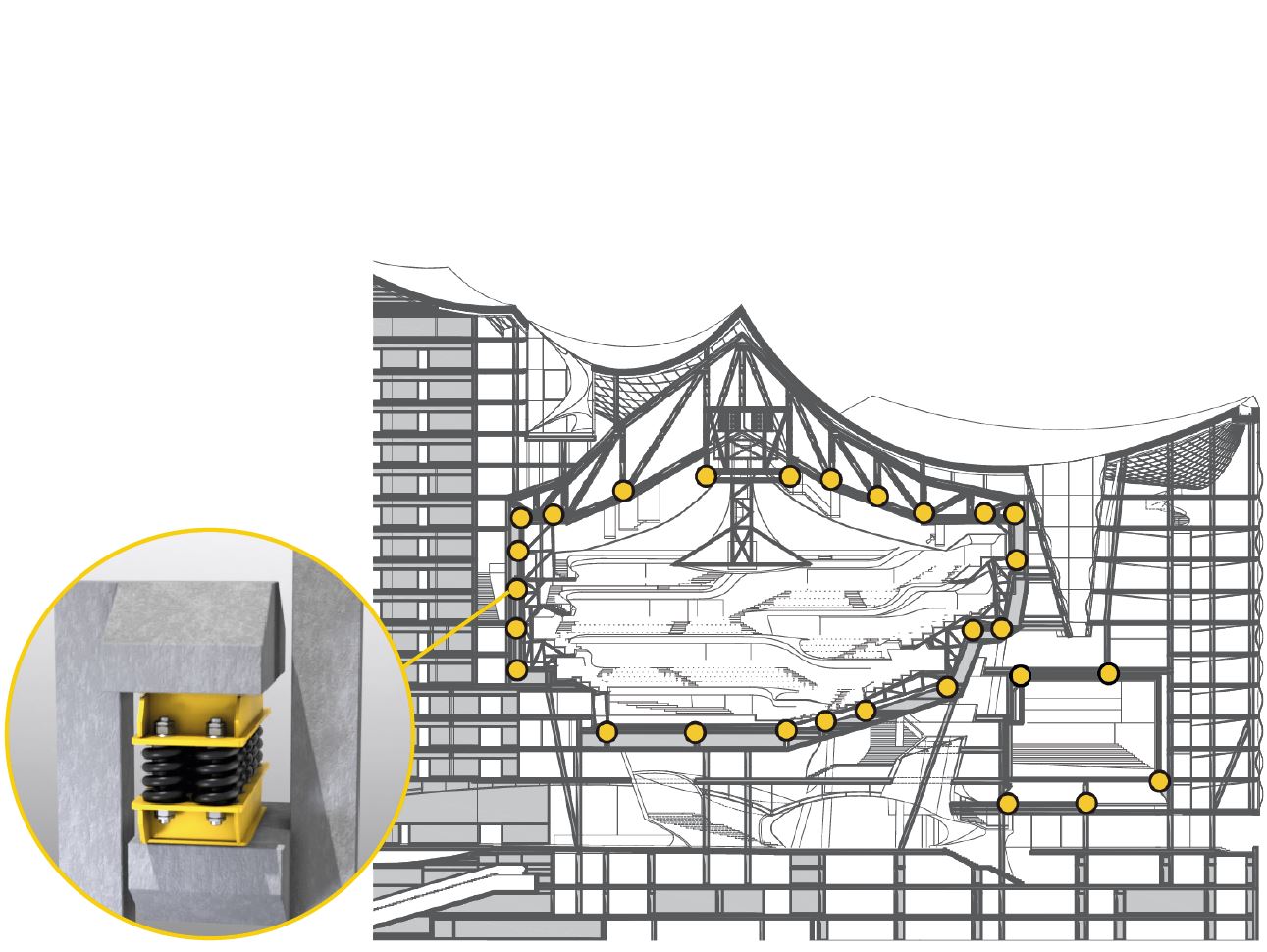

The two largest concert halls were designed as independent structures within the Elbphilharmonie. The halls are connected to the main building via helical steel springs, which act as a vibration barrier and prevent the transmission of structure-borne noise. The design of an isolated room in a larger structure is also referred to as a box-in-box solution and serves to decouple structure-borne noise for both the sources and the receivers. This technology is therefore ideal for separating quiet areas with high acoustic requirements from noisy areas with urban use.

Technical Facts:

Structure: Box-in-box construction

Vibration Source: Structure-borne noise from the environment and loud music in the concert halls

Design load: Great concert hall – 90,000 kN (2150 seats). Recital Hall – 20,000 kN (550 seats)

Base Isolation: 418 Pre-stressable GERB GP-spring elements

Support frequency: Great hall: 4.5 Hz. Recital hall: 3.5 Hz

Implementation

The Recital hall and the Great Concert hall float in the main building of the Elbphilharmonie and are completely acoustically decoupled – no

structure-borne noise penetrates or escapes via the helical steel spring elements. The challenge of combining acoustically demanding concert

halls with urban uses and public areas in one building was successfully designed and implemented. Today, world-famous artists and orchestras

perform in the Elbphilharmonie, one of the best concert halls in the world.

Further Resources

You need further information on this topic?

Please do not hesitate to contact us with your individual question.

One of our project engineers will get back to you shortly.

Protecting Elbphilharmonie from sound transmissions

In 2017 Hamburg received a new landmark.

The Elbphilharmonie is located south of the Speicherstadt, the historic warehouse district in the Port of Hamburg, Germany. The Elbphilharmonie was built on an existing structure of a brick quay warehouse and claims to be a „cultural monument for everyone“. The

building consists of different areas, concert halls and public areas as well as hotel and residential uses.

Protecting Elbphilharmonie from sound transmissions

In 2017 Hamburg received a new

landmark.

The Elbphilharmonie is located south of the Speicherstadt, the historic warehouse district in the Port of Hamburg, Germany. The Elbphilharmonie was built on an existing structure of a brick quay

warehouse and claims to be a „cultural monument for everyone“. The building consists of different areas, concert halls and public areas as well as hotel and residential uses.

Challenge

The Great Concert Hall, the heart of the Elbphilharmonie, offers a soundscape that

inspires. The sound architecture comes from the world-renowned acoustic designer Yasuhisa Toyota. Classical music has to sound perfect – not only does the shape of the hall play a decisive role here, but also noise coming in from outside has to be eliminated. Low-frequency sound from ship‘s horns and impact noise from the environment could penetrate the hall as structure-borne noise.

In addition, the building around the concert halls has to be protected from the music to ensure a quiet atmosphere in the surrounding hotel and residential areas during concerts.

Solution

Technical Facts:

Structure: Box-in-box construction

Vibration Source: Structure-Borne Noise from the environment

and loud music in the concert halls

Design Load: Great concert Hall: 90,000 kN (2150 seats)

Recital Hall: 20,000 kN (550 seats)

Base Isolation: 418 Prestressable GERB GP-spring elements

Support frequency: Great concert Hall: 4.5 Hz

Recital Hall: 3.5 Hz

The two largest concert halls were designed as independent structures within the Elbphilharmonie. The halls are connected to the main building via helical steel springs, which act as a vibration barrier and prevent the transmission of structure-borne noise. The design of an isolated room in a larger structure is also referred to as a box-in-box solution and serves to decouple structure-borne noise for both the sources and the receivers. This technology is therefore ideal for separating quiet areas with high acoustic requirements from noisy areas with urban use.

Challenge

The Great Concert Hall, the heart of the Elbphilharmonie, offers a soundscape that inspires. The sound architecture comes from the world-renowned acoustic designer Yasuhisa

Toyota. Classical music has to sound perfect – not only does the shape of the hall play a decisive role

here, but also noise coming in from outside has to be eliminated. Low-frequency sound from ship‘s horns and impact noise from the environment could penetrate the hall as structure-borne noise.

In addition, the building around the concert halls has to be protected from the music to ensure a quiet atmosphere in the surrounding hotel and residential areas during concerts.

Solution

The two largest concert halls were designed as independent structures within the Elbphilharmonie. The halls are connected to the main building via helical steel springs, which act as a vibration barrier and prevent the transmission of structure-borne noise. The design of an isolated room

in a larger structure is also referred to as a room-in-room solution and serves to decouple structure-borne noise for both the sources and the receivers. This technology is therefore ideal for separating quiet areas

with high acoustic requirements from noisy areas with urban use.

Technical Facts:

Structure: Box-in-box construction

Vibration Source: Structure-Borne Noise from the environment

and loud music in the concert halls

Design load: Great concert Hall: 90,000 kN (2150 seats)

Recital Hall: 20,000 kN (550 seats)

Base Isolation: 418 Prestressable GERB GP-spring elements

Support frequency: Great concert Hall: 4.5 Hz

Recital Hall: 3.5 Hz

Implementation

The Recital hall and the Great Concert hall float in the main building of the Elbphilharmonie and are completely acoustically decoupled – no structure-borne noise penetrates or escapes via the helical steel spring elements. The challenge of combining acoustically demanding concert halls with urban uses and public areas in one building was successfully designed and implemented. Today, world-famous artists and orchestras perform in the Elbphilharmonie, one of the best concert halls in the world.

Implementation

The Recital hall and the Great Concert hall float in the main building of the Elbphilharmonie and are completely acoustically decoupled – no structure-borne noise penetrates or escapes via the helical steel spring elements. The challenge of combining acoustically demanding concert halls with urban uses and public areas in one building was successfully designed and implemented. Today, world-famous artists and orchestras perform in the Elbphilharmonie, one of the best concert halls in the world.

Share this post

Further Resources

You need further information on this topic?

Please do not hesitate to contact us with your individual question.

One of our project engineers will get back to you shortly.

Further Resources

You need further information on this topic?

Please do not hesitate to contact us with your individual question.

One of our project engineers will get back to you shortly.